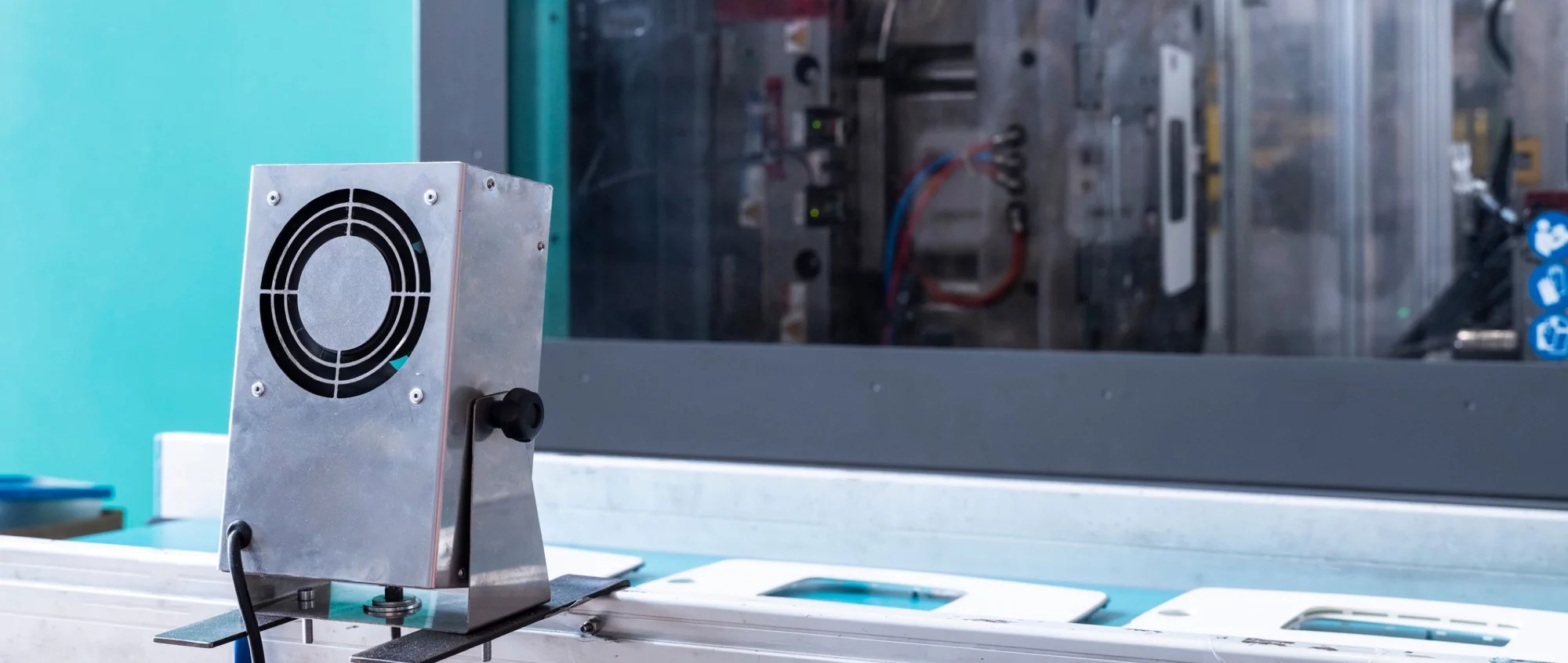

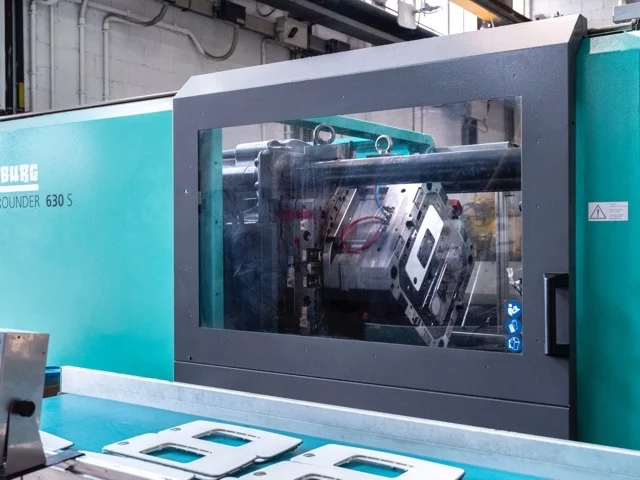

Mono injection

molding

Our highly specialised engineering and technopolymer and/or commodity molding offers production of components with highly technical characteristics and sophisticated designs.

ERREBI also offers gas-assisted injection molding (GAIM).

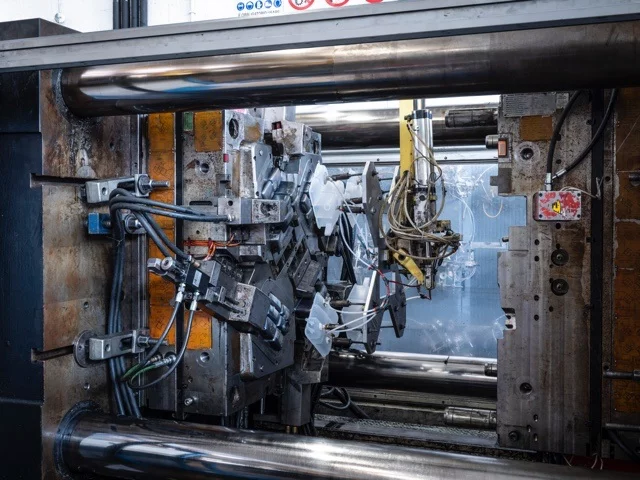

Bi-injection

molding

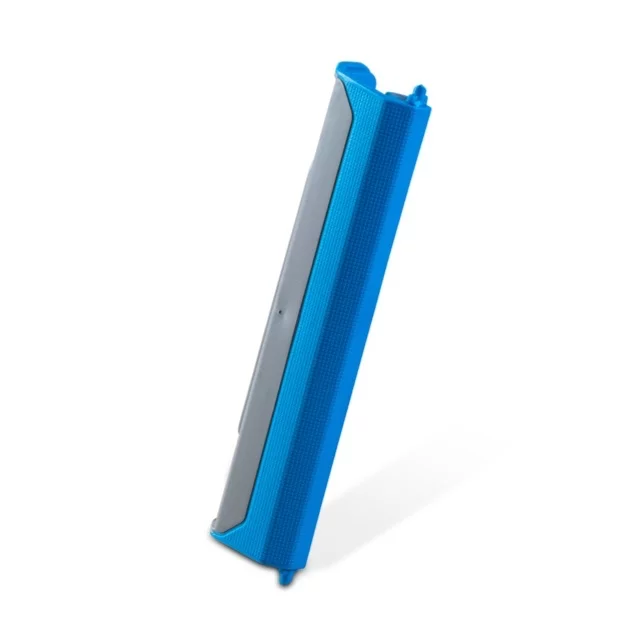

Bi-injection molding allows the creation of parts or products with two different plastic materials that are injected in the same mold.

The main advantage of bi-injection molding is the ability to create parts that combine the unique characteristics and properties of both types of plastic used. The choice of materials and the appropriate molding process guarantee the chemical bond between the two materials and their correct adhesion.

Overmolding inserts made of metal, plastic or other materials.

Overmolding injects plastic into a mold that contains inserts (e.g. plastic or metal) to create an assembly of multiple components.

The process meets aesthetic, functional, mechanical and physical (thermal or electrical conductivity) requirements, while eliminating the need for subsequent assembly or welding to improve production efficiency.

Technical expertise, precision, reliability and on-time delivery: Let us mold the product you want.

We transform different materials for different needs

The materials we use most:

Acrylonitrile Butadiene Styrene (ABS)

Polypropylene (PP)

Polycarbonate (PC)

Polyamide (PA)

Polybutylene Terephthalate (PBT)

Thermoplastic Elastomer (TPE)

Polyvinyl Chloride (PVC)

Polystyrene (PS)

Polymethyl Methacrylate (PMMA)

Polyacetal (POM)

High-Density Polyethylene (HDPE)

Low-Density Polyethylene (LDPE)

Linear Low-Density Polyethylene (LLPDE)